Petrochemicals & Refineries

VUP offers specialized products and services for petrochemicals, focusing on quality, safety, and process optimization.

Key Applications

Fuel Processing, Storage & Stability

Ensuring fuel stability during processing, transportation, and storage is critical to prevent degradation, gum formation, and maintain quality specifications.

Petrochemical Synthesis & Specialty Intermediates

The petrochemical industry requires a wide range of specialized intermediates for downstream applications or specific process needs, often demanding custom chemical synthesis capabilities.

Raw Materials for Downstream Industries

Refineries and petrochemical plants provide the fundamental building blocks for numerous downstream industries like polymers, plastics, coatings, and adhesives. Suppliers of intermediates for these sectors are key partners.

Process Optimization, Analysis & Safety

Optimizing refinery and petrochemical processes, ensuring product quality, and maintaining high safety standards requires robust analytical support and technical expertise.

Industry Challenges

Discover the unique challenges faced by Petrochemicals & Refineries and how VUP Solutions can help overcome them.

Fuel Processing, Storage & Stability

Challenge:

Ensuring fuel stability during processing, transportation, and storage is critical to prevent degradation, gum formation, and maintain quality specifications.

VUP Solutions:

We produce specialized additives like VUPIN H37-B (Antioxidant/UV Stabilizer) designed for fuel processing and storage. Additionally, our expertise extends to polymerization inhibitors like H-TEMPO, which has been successfully used for years in refinery FCC units (e.g., at Slovnaft) to prevent unwanted reactions.

Relevant Products

View all products

VUPIN H37-B Polymerization Inhibitor

A liquid polymerization inhibitor formulation combining 4-Hydroxy-TEMPO with 2-Butoxyethanol solvent. Prevents unwanted polymerization in petrochemical streams, monomer handling, and FCC gasoline applications.

Key Properties

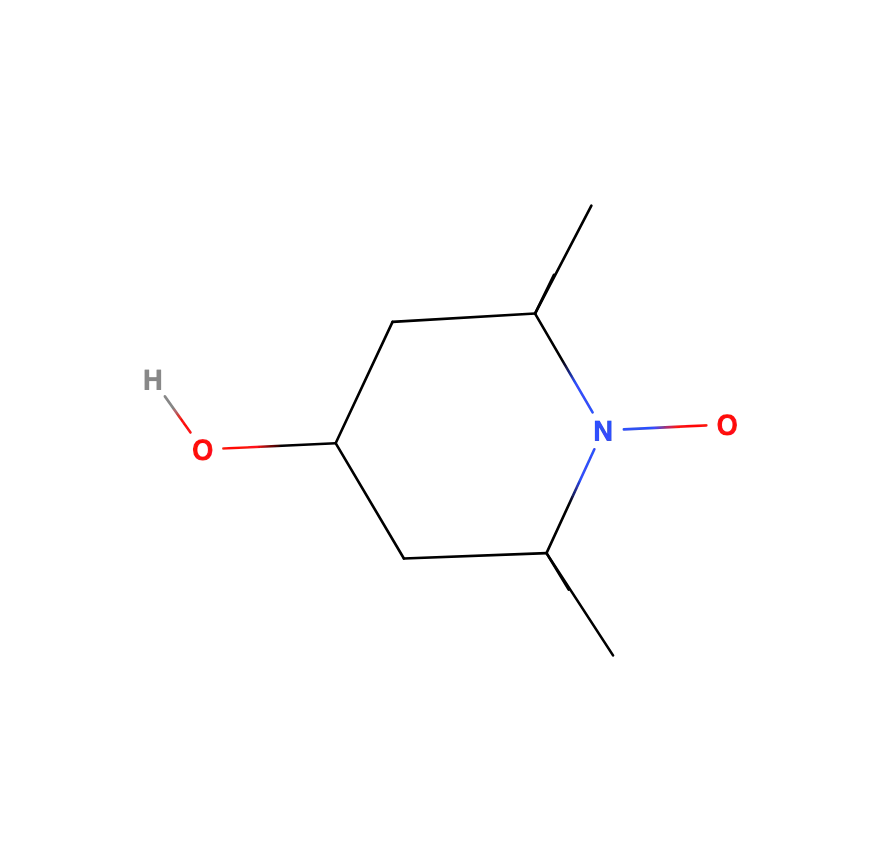

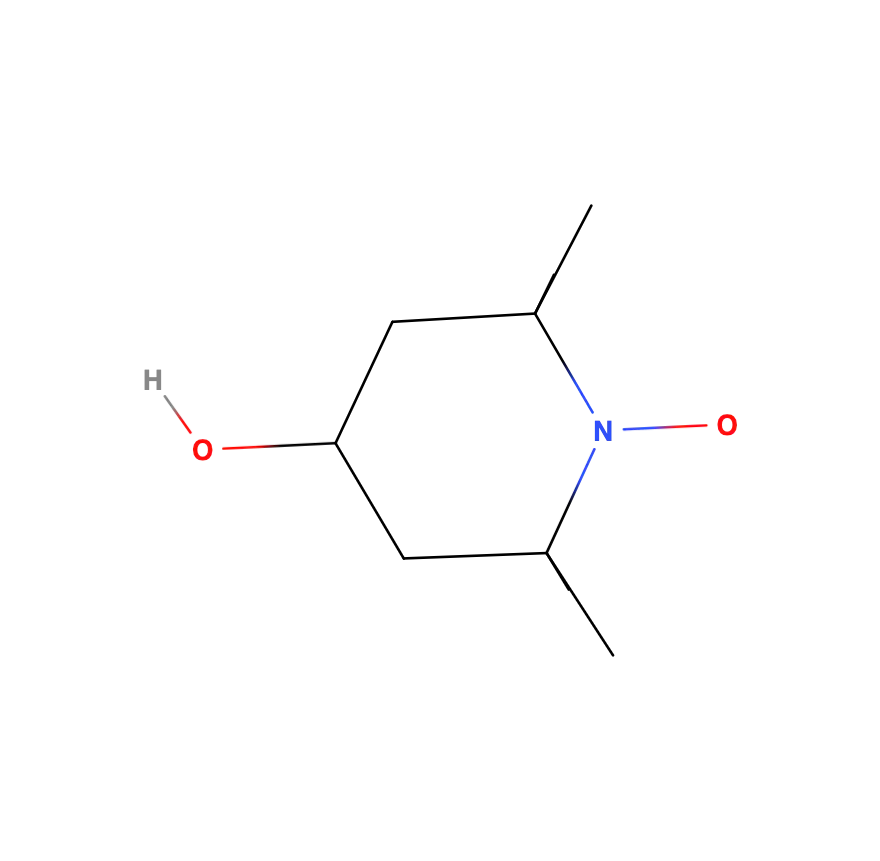

4-Hydroxy-TEMPO (TEMPOL / H-TEMPO)

A key functionalized derivative of TEMPO featuring both a stable nitroxyl radical and reactive hydroxyl group. Serves as a versatile antioxidant, catalyst, spin label, and crucial intermediate for synthesizing specialty chemicals.

Key Properties

Relevant Services

View all services

Research & Development

VUP's R&D division solves complex chemistry challenges across diverse industries.With 70+ years of chemical expertise, we transform ideas into viable technological solutions tailored to your needs.

Accreditations

Accredited Analytical, Technical-Safety & Environmental Services

The ATBEL (Analytical, Technical-Safety, and Environmental Laboratories) division is a specialized testing center within VUP, a.s., providing expert analytical services to both internal R&D projects and external partners. We deliver reliable, accredited results under SNAS Certificate No. S-118 (ISO/IEC 17025) and ISO 9001, ensuring the highest standards of quality and precision. Our services are led by division head Ing. Ľudovít Žiak, PhD.

Accreditations

Petrochemical Synthesis & Specialty Intermediates

Challenge:

The petrochemical industry requires a wide range of specialized intermediates for downstream applications or specific process needs, often demanding custom chemical synthesis capabilities.

VUP Solutions:

Leveraging our strong R&D foundation, we offer Custom Synthesis services for specialty organic intermediates. Our historical and ongoing research expertise includes areas directly relevant to petrochemical feedstocks and derivatives, such as acetylenic alcohols, epoxides, polyhydric alcohols, higher aldehydes, and brominated hydrocarbons.

Relevant Services

View all servicesRaw Materials for Downstream Industries

Challenge:

Refineries and petrochemical plants provide the fundamental building blocks for numerous downstream industries like polymers, plastics, coatings, and adhesives. Suppliers of intermediates for these sectors are key partners.

VUP Solutions:

We manufacture key intermediates like DMPA, DMBA, and HPVA, which are derived from petrochemical value chains and are essential raw materials for producing high-performance polyurethanes (PUDs), polyesters, and alkyds used extensively in coatings, adhesives, and polymer applications.

Relevant Products

View all products

Dimethylolbutyric Acid (DMBA)

An advanced trifunctional intermediate enabling next-generation waterborne resins. Facilitates solvent-free PUD synthesis with lower processing temperature and enhanced film resistance.

Key Properties

Dimethylolpropionic Acid (DMPA)

Essential trifunctional intermediate enabling high-performance waterborne coatings, polyurethane dispersions, alkyds, and polyesters with superior stability and environmental benefits.

Key Properties

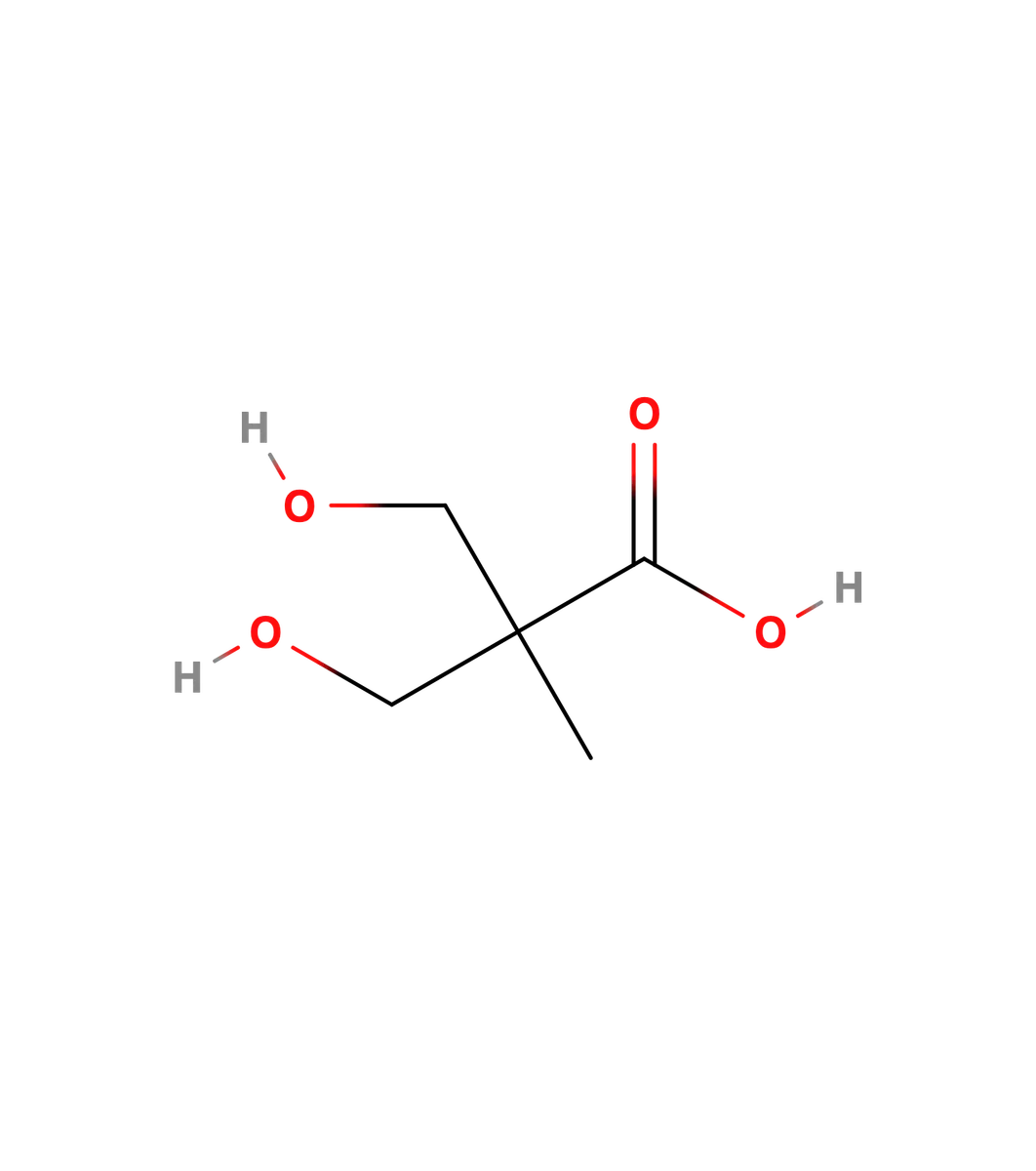

3-Hydroxypivalic Acid (HPVA)

A unique hydroxy acid featuring a neopentyl structure, essential for synthesizing high-performance polyesters and esters with exceptional hydrolytic stability, thermal stability, and weather resistance.

Key Properties

Relevant Services

View all servicesProcess Optimization, Analysis & Safety

Challenge:

Optimizing refinery and petrochemical processes, ensuring product quality, and maintaining high safety standards requires robust analytical support and technical expertise.

VUP Solutions:

Our R&D services can assist with process development and optimization. Our accredited ATBEL Division (SNAS S-118) provides comprehensive analytical services relevant to this sector, including gas/liquid chromatography for composition analysis, VOC determination, physical property testing, and extensive technical-safety analyses (flash point, flammability, etc.) crucial for safe handling and process control.

Relevant Services

View all services

Research & Development

VUP's R&D division solves complex chemistry challenges across diverse industries.With 70+ years of chemical expertise, we transform ideas into viable technological solutions tailored to your needs.

Accreditations

Accredited Analytical, Technical-Safety & Environmental Services

The ATBEL (Analytical, Technical-Safety, and Environmental Laboratories) division is a specialized testing center within VUP, a.s., providing expert analytical services to both internal R&D projects and external partners. We deliver reliable, accredited results under SNAS Certificate No. S-118 (ISO/IEC 17025) and ISO 9001, ensuring the highest standards of quality and precision. Our services are led by division head Ing. Ľudovít Žiak, PhD.